Services

"Klaipėdos NK centras"

offers non-destructive testing services during metal structure production as well as the inspection of the operating objects in various industrial sectors worldwide

LIQUID PENETRANT TESTING (PT)

Dye penetrant testing (PT) method is used to find visible defects on the surface (splits, pores). PT is known as the most sensitive method for metal and other surfaces.

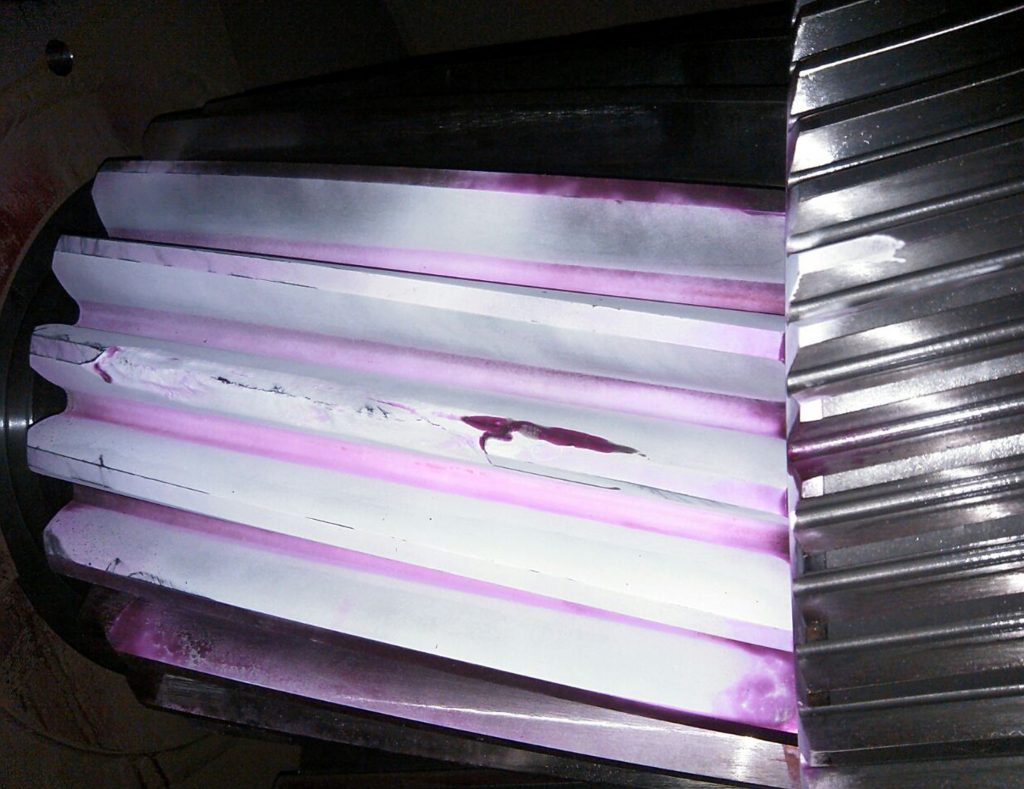

MAGNETIC PARTICLE INSPEC. (MT)

Magnetic particle inspection (MT) is used to search for surface and subsurface discontinuities in ferromagnetic materials.

VISUAL TESTING (VT)

Visual inspection method allows to detect surface defects, deviations of the specified sizes and shapes. It is the simplest and most affordable non-destructive testing method, however, can be very effective for defect prevention and detection.

EDDY CURRENT TESTING (ET)

Eddy current testing (ET) is used to search for surface and subsurface defects. The method is used only for checking electrically conductive materials.

ULTRASINIC TESTING (UT)

Ultrasonic method is used to detect defects in various materials. It is one of the most commonly used methods for testing welding joints. The advantage of the UT - high accuracy in determining the location of defects.

ULTRASONIC THICKNESS MEASUREMENT (UTM)

Read More...

ULTRASONIC THICKNESS GAUGING (UTM)

One of the most commonly used methods for evaluating technical condition of steel structures is ultrasonic thickness measurement (UTM).

Klaipedos NK centras is committed to maintaining professional technical knowledge, high quality non-destructive testing services, customer satisfaction and integrity by delivering quality services conforming to industry standards.

Our Services

Get In Touch

Strevos str. 3a, LT-93240, Klaipeda, Lithuania

+370 650 91030

info@nk-centras.lt